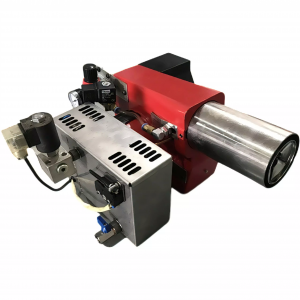

At Career Burner, we recognize that utilizing waste oil as a fuel source comes with its own set of unique challenges, especially concerning viscosity. The thickness or viscosity of waste oil plays a critical role in the operation of waste oil fuel burners, as it directly impacts key factors such as atomization, combustion efficiency, and overall burner performance. If the viscosity is too high, it can lead to incomplete combustion, while oil that is too thin may not atomize properly, resulting in reduced efficiency. In this article, we will delve into the importance of viscosity and explain how our advanced waste oil fuel burner systems are specifically engineered to effectively manage a range of oil consistencies. We will explore the innovative technologies and design features that allow our systems to optimize combustion, ensuring clean, efficient, and reliable operation regardless of the viscosity of the waste oil being used.

Table of Contents

ToggleThe Importance of Proper Atomization

One of the key factors in efficient waste oil combustion is proper atomization. Our waste oil fuel burners use compressed air to break down the oil into fine droplets, ensuring complete and clean combustion. This method is particularly effective with high-viscosity oils, as the compressed air helps overcome thickness issues that might otherwise lead to clogging or incomplete burning. Additionally, this system operates quietly, making it suitable for environments where noise reduction is important.

Manual Flow Regulation for Optimal Performance

Another advantage of our waste oil fuel burner design is manual flow regulation. This feature allows users to adjust the oil flow based on viscosity changes, ensuring optimal performance even when dealing with different waste oil types. Whether the oil is thin or thick, the burner can be fine-tuned to maintain steady combustion without unnecessary waste or emissions.

Easy Maintenance for Long-Term Reliability

Maintenance is also a critical consideration when working with waste oil, as residue buildup can affect burner efficiency. Our atomizing devices are designed for easy servicing—routine maintenance can be performed without removing the entire unit, saving time and reducing downtime. This user-friendly approach ensures that the burner remains in top condition, even with frequent use of high-viscosity waste oils.

Conclusion

Viscosity plays a crucial role in the performance of a waste oil fuel burner, affecting atomization, combustion quality, and long-term reliability. At Career Burner, we’ve engineered our systems to handle varying oil consistencies with features like compressed air atomization, manual flow regulation, and easy maintenance. If you’re looking for a dependable waste oil fuel burner that adapts to different viscosity levels, our solutions are designed to deliver consistent, efficient performance. Contact us to learn more about our products and how they can meet your specific needs.