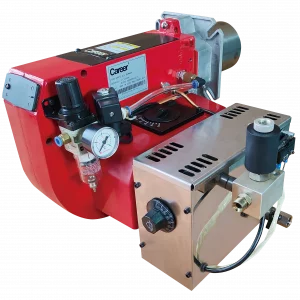

For three decades, we at Career Burner have engineered combustion systems that transform complex waste streams into reliable thermal energy. Industrial operators know this truth intimately: waste oil combustion fails at the nozzle first. When recycled lubricants, machining coolants, or industrial sludges enter the combustion chamber, their variable viscosity and contaminant loads demand purpose-built atomization solutions. Standard nozzles – designed for uniform fuels – clog, erode, or produce unstable flames within weeks, triggering costly shutdowns and emission violations. This article distills our field experience into actionable insights on nozzle selection.

Table of Contents

ToggleAtomization Functionality for Variable Waste Oil

Waste oil burner nozzles primarily serve to atomize fuel into a fine mist for complete combustion. Conventional nozzles struggle with inconsistent waste oil quality, leading to clogging or uneven spray patterns. We design nozzles with enlarged flow paths and hardened materials to resist particulates common in recycled oils. Their geometry ensures precise droplet size distribution even with fluctuating viscosity – maintaining stable flame characteristics without manual intervention during operation.

Corrosion Resistance in Aggressive Fuel Environments

Material compatibility remains non-negotiable. Waste oils often contain acids, solvents, or metal particles that erode standard components. Our nozzles utilize tungsten-carbide cores and stainless-steel bodies to withstand corrosion while operating at temperatures exceeding 800°C. This durability is verified through 100% pre-shipment combustion testing, guaranteeing reliability in demanding applications like metalworking furnaces or hazardous waste incineration.

Optimizing Nozzle-System Synergy

The nozzle’s effectiveness depends entirely on its integration within the full industrial waste oil burner system. We ensure seamless compatibility between nozzle dynamics and our combustion chambers’ airflow geometry. This coordination maintains precise pressure differentials across viscosity ranges – critical when processing heavy sludges or diluted waste streams. Without this engineered harmony, even advanced nozzles fail to achieve complete combustion or stable ignition cycles.

Proactive Maintenance for Sustained Efficiency

Operational maintenance demands proactive planning. Nozzle wear directly impacts fuel efficiency and emissions. We recommend quarterly inspections for high-utilization systems. Key indicators include changes in flame shape or unexpected soot accumulation. For critical processes, keep spare nozzles calibrated to your specific fuel blend – our precision customization ensures seamless interchangeability.

Conclusion

Optimizing nozzle performance requires balancing material science, fluid dynamics, and real-world fuel variability. With Career Burner’s waste oil burner series – engineered for heavy industrial use – you gain consistent combustion stability even with substandard fuels. Explore our application-tailored solutions designed for 12/24VDC off-grid or vehicular systems, and request your combustion performance analysis today.