Industrial furnace burners are the backbone of many industrial heating processes. They provide the heat necessary for applications such as metal melting, chemical processing, and materials drying. Without a properly functioning and correctly selected burner, industrial operations face spiraling costs, reduced output, and environmental non-compliance.

Career Burner understands the critical role these burners play, and this guide aims to discuss different types of industrial furnace burners, their functions, and how to select the right one for your needs!

Understanding Industrial Furnace Burners

An industrial furnace burner is a device designed to mix fuel and air to produce a controlled flame that heats industrial furnaces. The main function is to generate the required thermal energy efficiently and safely. These burners are fundamental in processes like heating metals, melting raw materials, smelting ores, and other heat-intensive industrial applications.

A typical furnace burner system consists of three key components:

- Fuel Source: The mechanism that delivers the fuel (e.g., natural gas line, oil pump, and atomizer) to the combustion zone.

- Air Supply: A fan or blower system that provides the necessary amount of air for complete, clean, and efficient combustion. This air can be delivered as forced draft or induced draft.

- Ignition System: A spark igniter or pilot flame that provides the initial heat source to start the main flame.

In addition to the above three key components, there are integrated control and safety systems, which typically include a flame monitoring device, a programmable logic controller (PLC) for regulating the fuel-air ratio, and various safety shut-off valves and sensors. These integrated elements work together to optimize combustion efficiency, ensure operational reliability, and meet stringent environmental and safety standards.

Types of Industrial Furnace Burners

There are three primary categories of industrial furnace burners, which are:

These are among the most common, designed to operate on gaseous fuels like natural gas or propane. They are favored for their clean burn, precise temperature control, and often lower operating costs in regions with abundant gas supply. They can be atmospheric, fan-assisted, or high-velocity.

- Oil Furnace Burners

These burners are designed for liquid fuels such as light oil, heavy oil, or waste oil. They typically require an atomizer to break the liquid fuel into a fine spray for proper mixing and combustion. Oil furnace burners are often preferred in areas where gas supply is unreliable or where oil is more economical.

Product shown: FX20 Automatic Waste Oil Burner

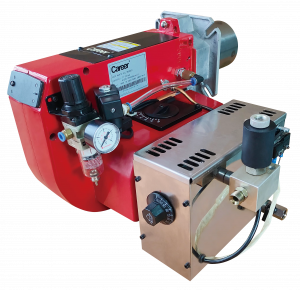

- Dual-Fuel Furnace Burners

Offering the highest degree of flexibility, dual-fuel burners can operate on two different fuels, typically gas and oil. This capability is crucial for industrial plants that require fuel switching based on price fluctuations, availability, or environmental regulations.

We at Career Burner design and manufacture a broad spectrum of these technologies, including specialized ultra-low NOx burners, to meet the diverse and evolving needs of our global clients. Our product line is built to maximize efficiency and minimize emissions across various industrial applications.

Key Factors to Consider When Choosing a Furnace Burner

Think carefully to choose the right industrial furnace burner, as your decision will impact everything from your utility bills to your environmental footprint. Key considerations include:

- Fuel Type Availability and Cost

The most fundamental factor. You must assess the long-term price stability, supply reliability, and infrastructure costs (piping, storage tanks) for gas fuels versus various types of oil before committing to a gas furnace burner or an oil furnace burner.

- Burner Capacity and Heat Output Requirements

The burner must be sized correctly to match the maximum and minimum heat demands of the furnace. Undersizing leads to slow heating and process bottlenecks, while oversizing can reduce efficiency and increase cycling.

- Efficiency and Emission Standards

Modern burners focus heavily on maximizing fuel efficiency (reducing consumption) and minimizing harmful emissions, particularly nitrogen oxides (NOx) and carbon monoxide (CO). Compliance with local and international environmental regulations is non-negotiable, making low-NOx technology a crucial consideration.

Product shown: NXQEF-3.0 Low NOx Gas Burner

- Maintenance Needs and Operational Reliability

Examine the burner’s design for ease of maintenance. Complex systems with proprietary parts may lead to longer downtimes. Reliability is paramount, as a burner failure can halt an entire production line.

- Compatibility with Existing Furnace Systems

The new burner must seamlessly integrate with the existing furnace shell, refractory materials, control systems, and safety interlocks. Retrofitting an existing furnace requires careful engineering to ensure optimal performance.

At Career Burner, we offer custom industrial burner solutions tailored to specific needs. If you need any support, you are more than welcome to reach out to us!

Industrial Furnace Burner Maintenance and Troubleshooting Tips

Regular checks and timely fixes keep your burners efficient and safe—here are some tips to follow.

- Routine Inspection and Cleaning

- Daily/Weekly Checks: Visually inspect the flame for color and stability. Check for any unusual noises or vibrations.

- Monthly/Quarterly Cleaning: Ensure the air inlet screen and fan blades are clean to maintain proper air-to-fuel ratios. Clean the gas furnace burner ports or the atomizer tips of the oil furnace burner to prevent blockages.

- Annual Tune-up: Schedule a professional service to calibrate the air-fuel ratio using a combustion analyzer. This is the single most effective way to maintain peak efficiency and lower emissions.

- Common Issues and Troubleshooting

- Flame Instability (Lifting or Pulsating): Often caused by incorrect air-to-fuel ratio, too much draft, or blockages in the burner head. Check pressures and adjust the damper settings.

- Soot Buildup (Oil Burners): Indicates incomplete combustion, usually due to insufficient air, poor atomization, or a dirty burner tip. Clean or replace the atomizer and verify the air setting.

- Fuel Leaks: A serious safety hazard. For gas burners, check pipe joints with a leak-detecting solution. For oil burners, inspect all fuel lines and fittings for cracks or drips. Immediate shutdown and repair are necessary.

Conclusion

In conclusion, industrial furnace burners are indispensable in many heat-intensive industrial processes. Understanding burner types, functions, and selection criteria will help you choose the best burner for your operation.

Whether you require a gas furnace burner, oil furnace burner, or other industrial burner types, Career Burner is ready to assist with quality products and expert advice to ensure your industrial furnace runs smoothly and efficiently!